We believe in creative solutions

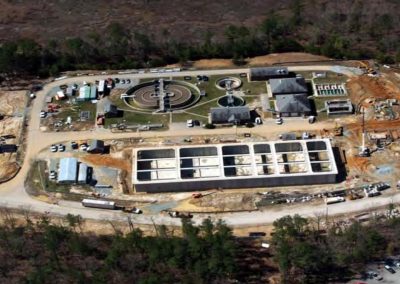

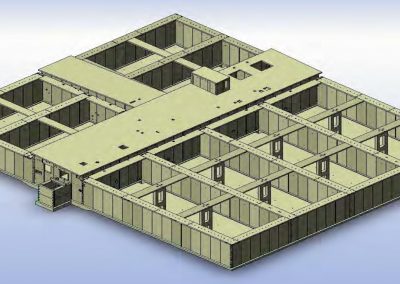

Dutchland specializes in designing, manufacturing, and installing package wastewater treatment plants and custom designed wastewater treatment plants. With over 30 years of experience, Dutchland offers clients a unique combination of engineering and process design, operations expertise and control systems implementation to allow for efficient execution of wastewater projects.

Over 30 Years

of Experience

Our Customers

- IBM

- United States Military Academy

- United States Air Force

- Baxter

- Alexandria Renew Enterprises

- Furmano’s

- PA American Water

- MillerCoors Brewing Company 14

- Perdue Farms

- GlaxoSmithKline

- Sanofi Pasteur

- The Hershey Company

- Army National Guard

- Ken’s Foods

- US Army Corps of Engineers

- Baltimore-Washington International Airport